On March 17, 2025, a Production & Operations Management class for second-year students of the School of Industrial Management took place at Hochiminh City University of technology, featuring guest speaker Luan Dinh (Director Sourcing Operation) from Adidas Sourcing.

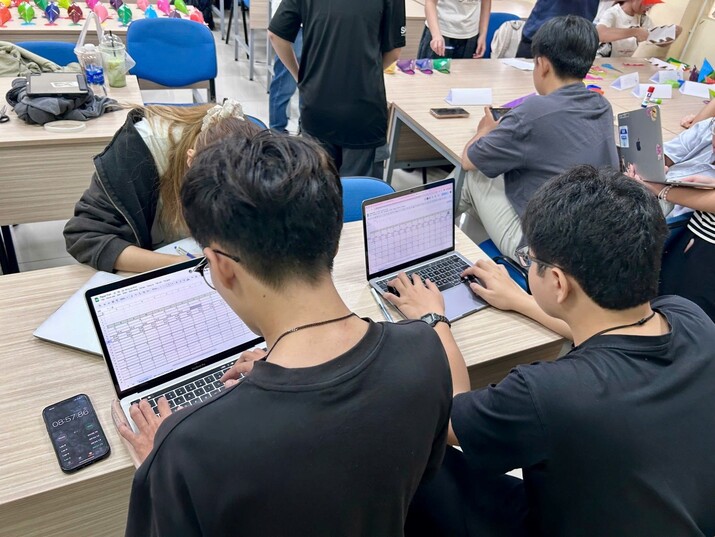

During the session, students practiced simulating a production line and used the stopwatch time study method to determine the standard time for producing a product. They received valuable feedback from the expert on analyzing waste in each of the production lines designed by their groups. Through this analysis, students clearly identified types of waste such as waiting time, excess inventory, and unnecessary processes, allowing them to draw valuable lessons on how to optimize production processes.

Additionally, many useful insights were shared with the students by the expert, including designing and laying out production line diagrams: recognizing and applying different layout types in production to select the appropriate design for product lines; classifying value-added, non-value-added, and non-value-added but necessary activities in the production process, leading to a deeper understanding of the operations at each stage. Students were also introduced to the roles and responsibilities of industrial engineers, emphasizing their role in optimizing processes and minimizing waste. Finally, learning about line balancing helped students grasp how to allocate working time and waiting time effectively to enhance overall production line efficiency. This experience from the class not only helped students develop analytical skills but also increased their ability to apply theory to practice. The knowledge and experience gained from the session broadened students’ perspectives on improving processes and enhancing efficiency in the industry.